ExxonMobil™ polymers for the packaging industry

New lighter, more durable packaging materials.

The ExxonMobil™ product range provides solutions for various applications:

Bags and sacks

ExxonMobil™ performance polymers enable the high-speed production of medium- to heavy-duty sacks with extreme levels of strength.

The main applications of these products are food packaging, lawn and garden products, fertilisers and resins.

Shopping bags, liners and bin bags

Performance polymers can reduce the thickness of high-density polyethylene (HDPE) films for shopping and waste bags without compromising strength.

Containers, cups and tubs

Performance polymers offer accessible, effective solutions for rigid packaging applications such as food containers, cups and tubs but also thermoformed packaging, thin-wall injection-moulded (TWIM) containers and rotomoulded containers.

The main benefits of performance polymers are impact strength, flexibility, clarity, reduced stress whitening and ease of processing.

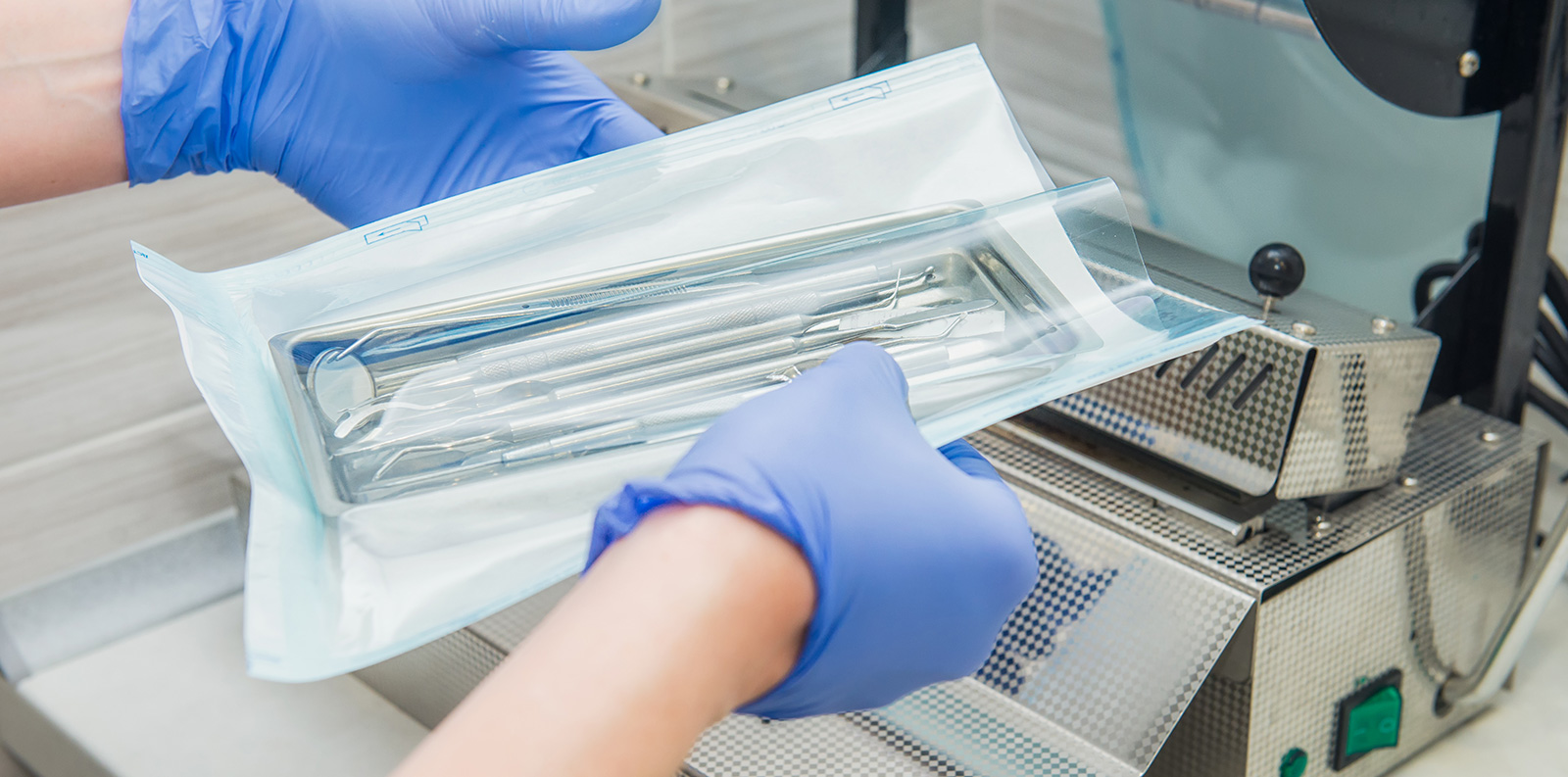

Caps, seals and closures

ExxonMobil™ polypropylene resins provide stiffness, toughness, impact strength, clarity, colour, protection, extended shelf life, low gel and faster processing through to the end product.

ExxonMobil™ supplies a wide range of polypropylenes offering high-performance plastic packaging solutions for applications such as caps, seals and closures for the beverage industry, sealant and coating products, etc.

Shrink packaging

ExxonMobil™ supplies optimised solutions combining excellent packaging integrity with preserved clarity and shine, ensuring that the product inside remains visible.

High integrity and holding force, the possibility of reducing the thickness and excellent reliability on high-speed packaging lines are some of the many advantages of EXXONMOBIL™’s range of products.

Hygiene and personal care

ExxonMobil™ offers a wide range of products and services providing support for your application needs in the hygiene and personal care industry, supplying solutions for hygiene products such as nappies, incontinence pads for adults and feminine care products

Flexible food packaging

To protect and preserve the integrity of food products such as cheeses, meats, bread and vegetables, ExxonMobil™ supplies flexible food packaging solutions that are extremely impact-resistant and can withstand tough environments such as freezers.

Advantages include impact strength, tear strength and flex-crack resistance, excellent sealing properties, outstanding optical properties, improved output and better film calibration.

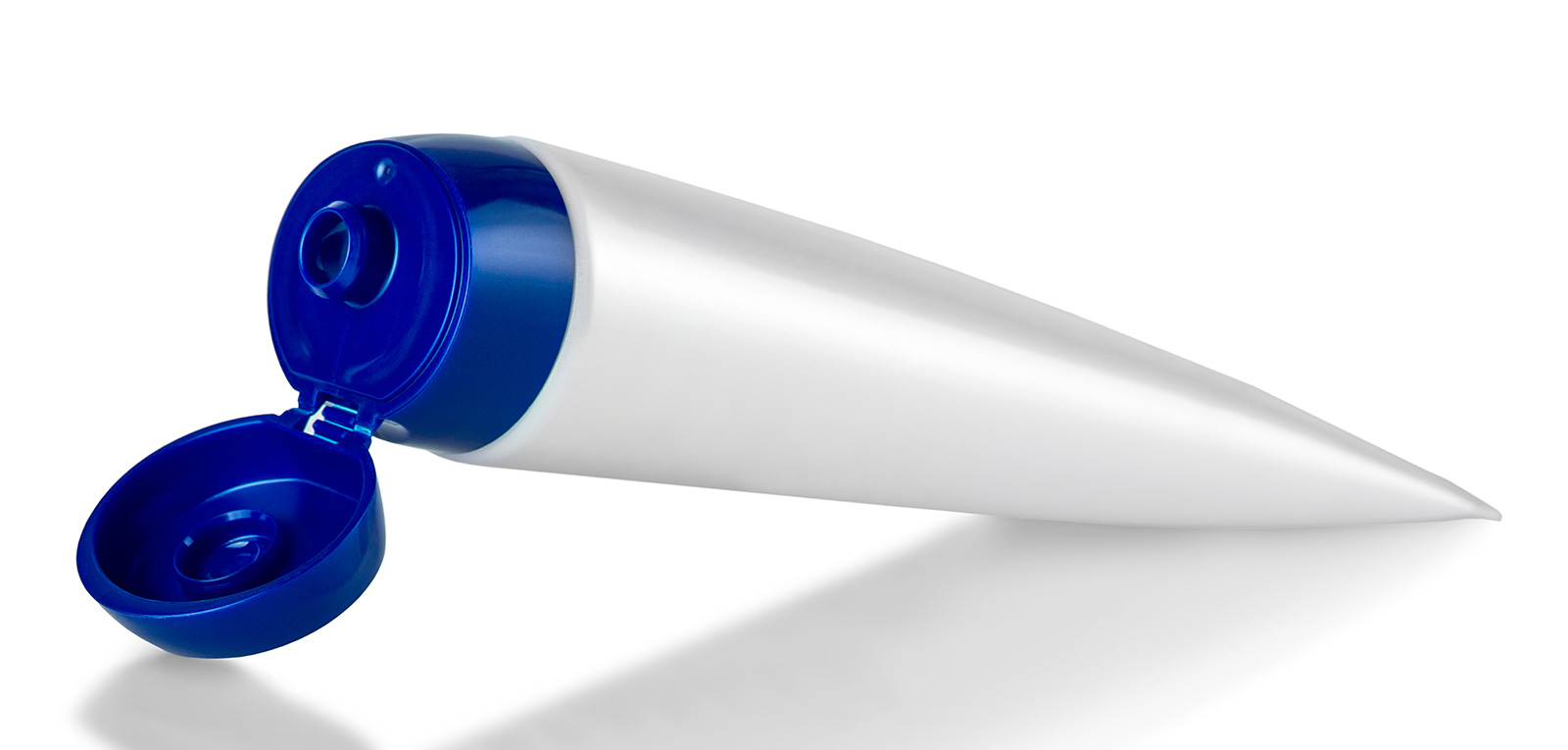

Lamination tubes

ExxonMobil™’s performance polymers supply high-performance packaging lamination tubes (lamitubes) that can withstand the most demanding stresses.

Common applications include cosmetics, health products, food and liquid products.

Liquid packaging

ExxonMobil™’s performance polymers help to protect and preserve liquid products such as wine, milk, oil, juice and detergents thanks to a product range offering advanced performance in terms of sealing, flexibility, impact strength and critical properties able to withstand the most demanding environments.

Other typical applications for liquid packaging include bag-in-box bladder films, pillow and stand-up pouch films that are laminated or non-laminated and flexi-tank container liners.

Pallet packaging

Performance polymers are useful for achieving optimum stability of both load and packaging.

These products can also withstand the most demanding stresses in terms of product protection.

Soft-shrink packaging

To package and group together packaging solutions from manufacturer to end user, ExxonMobil™ supplies specific packaging solutions and effective solutions to protect delicate or irregularly-shaped items.

The most common applications are delicate foods and irregularly-shaped products such as office supplies, stationery and air filters.